El Tren de la Muerte, literally translates to the train of death, but it refers to a freight train that starts its route in Chiapas state in southern Mexico, near the border of Guatemala heading to different points on the American border. Many of the dangers posed by this journey result from the train itself and the process of climbing aboard and getting off moving trains. Often, migrants fall asleep while riding atop trains and are jolted off and onto the tracks where many are killed instantly by decapitation, blood loss, and shock.

Wikipedia: La Bestia

On 2nd June 2023 at 19:26, two thousand two hundred hapless passengers travelling from the Howrah to Chennai, on the Coromandel express had just entered Chola mandala or the land of the Cholas. The eastern coastline was named Coromandel after the Portuguese occupation. The train ride was meant to be through the scenic coastal plains spanning 1,076 kms, studded with timeless world heritage sites. Little did they know they had literally boarded the train of death. The train was speeding through Bahanaga Bazaar, a nondescript town at 128 kms per hour. What was meant to be a breezy-uneventful minute turned into a bloody horror.

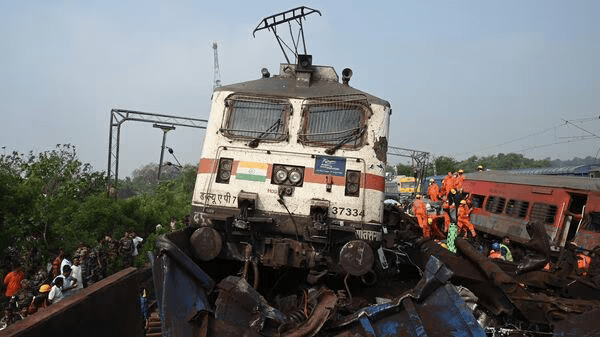

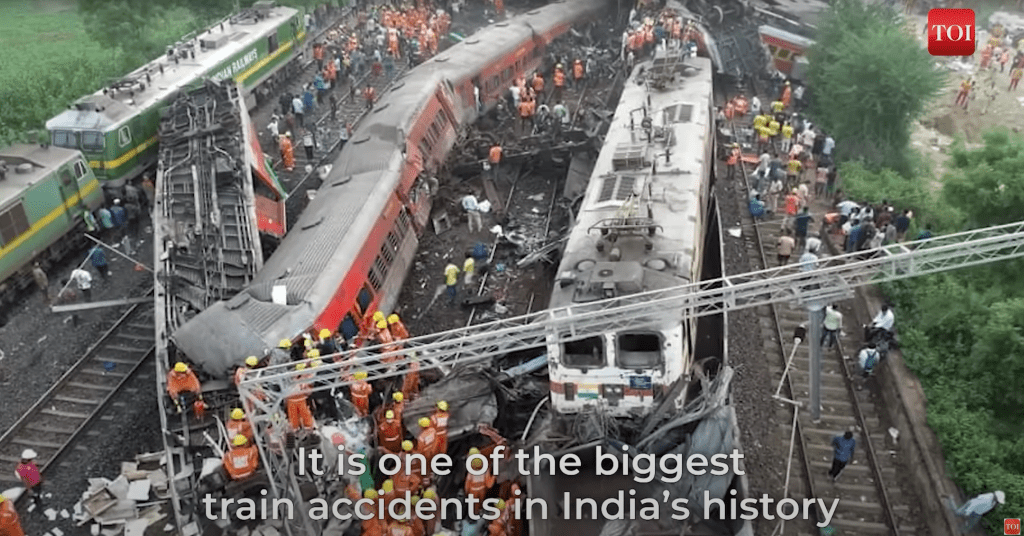

The train collided with a resolute goods train brimming with iron ore resulting in a chain of zigzag carriages that tail whipped another faultless Howrah-Yeshvantpur super fast express, triggering a mayhem of mangled carriages and destruction. 288 passengers were killed and over 900 were seriously injured, in one of India’s worst train accidents in 28 years, since the 1995 Firozabad rail disaster that killed 358 passengers.

While there are several theories none seem to fully explain what lead to the death and destruction. Especially how did an engine launch itself atop a goods train in a head on collision, wherein the engine survived largely unscathed. There are no signs of a collision. Everything from the windscreen, the wipers and even the cowcatcher remains intact on the engine. It almost appears like it sped off a ramp like a Robbie Madison’s motorcycle feat.

The official explanation from Jaya Verma Member of the Railway Board was as follows:

- Coromandel express was speeding at 128 kph, which means the signal was a green light, or else, it would not have been possible. Top permitted speed for the section was 130 kph.

- From the other side the Howrah-Yeshvantpur SFT was travelling at 126 kmph, the signal was green, the relative speed of the two trains was therefore 254kph.

- The preliminary finding was the accident was caused by a faulty signal

- Somehow it crashed into the goods train, the goods train was laden with iron ore, making it immovable, therefore the goods train remained unshaken, whereas the speeding Coromandel express was scattered, rebuffed by the weight of the iron ore carrying goods train

- The Coromandel express was operating LHB coaches, they are considered anti-telescopic, meaning they do not go through the other coach or flip in case of a collision. Each LHB coach also has an “advanced pneumatic disc brake system” for efficient braking at higher speeds. So clearly the speed and impact of the collision was extraordinary, to overwhelm such a system.

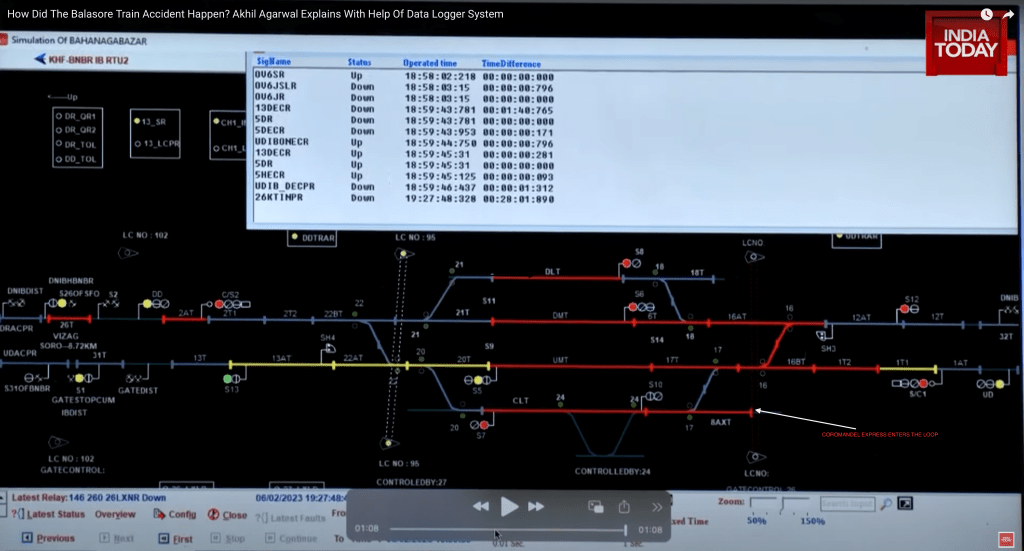

- The station had an electronic interlocking system (which has been represented in Figure 1)

- The Howrah Yeshvantpur SFT had almost passed Coramandel express it was a fraction of second behind, in which the last two coaches of the Howrah Yeshvantpur express collided with the Coromandel express and derailed the coaches

- The prima facie cause of the accident is known but cannot be shared until authorised by CRS or CRS publishes the report. CRS is Comission of Railway Safety which operates under the administrative control of Ministry of Civil Aviation of the Government of India. The current Minister is Jyotiraditya Scinda.

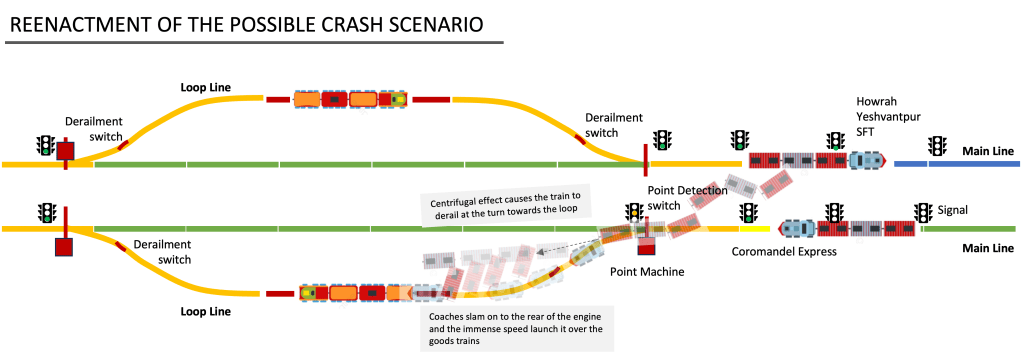

The train veered into the loop and crashed into the berthed train

“There was an unauthorised intervention in the signalling system, the route was set to loop line, wherein a heavy goods train was parked, whereas the signal showed green. The train was traveling at a very high speed, by the time the train driver realised it, it was too late and there was a collision, resulting in the massive tragedy that took place“, according to Sudhanshu Mani the ex General Manager of Integral Coach Factory, also known as the father of Vande Bharat. For this to have happened several things needed to have gone wrong.

Railway Safety Systems and Controls

Interlocking System

First, let us understand the operation of the interlocking system. In railway signalling, an interlocking is an arrangement of signal apparatus that prevents conflicting movements through an arrangement of tracks such as junctions or crossings. There are two types of interlocking system, Indirect and Electronic interlocking system. Indirect interlocking is when the point system, responsible for switching lines, is manually operated while the route and signalling is set via a control panel by the station master. Electronic interlocking is where the point system and signal are connected via an electronic circuit and the route is fully controlled via the control panel. It was confirmed by Jaya Verma in her press conference that Bahanaga Bazaar station operated an Electronic interlocking system. Which means, the point machine and the signalling system were integrated, all centrally controlled via a control panel.

There is a point machine that, through an automated system of gears, switches the tracks, in this case from the main line to the loop line. A point detection switch is in place, that transmits back to the control panel, the status of the track (reverse or normal) along with the active signal. The station master can use the control panel to set the route of the train. The panel lights up to indicate the status. If there is an obstacle there is a fail safe which will prevents the track change. In summary, the interlocking system ensures that two trains are not routed in the same direction, the track circuit determines if a section is down and it prevents switching.

For the loop line there is a route signal which indicates the direction of the route to be taken. The route signal is activated only when the point machine sets the track lines to the route. There are three signals apart from the route signal. Red meaning the train must stop, amber meaning the train must proceed slowly, green meaning the train is permitted to proceed at maximum speed. The route signal when activated is always amber which means a route change can only happen at slow speed. So if the route was set to the loop line, the signal must have been amber and not green.

Finally there is a derailment switch, the switch ensures a berthed train is derailed if it rolls back towards the main line from the loop line due to break failure.

Automatic Block System

Automatic Block Working is a system of train working in which movement of the trains is controlled by the automatic stop signals. These signals are operated automatically by the passage of trains into through and out of the automatic signalling sections. The following are the essentials of Automatic Block System.

Where trains are worked on Automatic Block System: –

- (a) The line is track circuited or axle counters are provided throughout its length and divided into a series of automatic signalling sections each of which is governed by an Automatic Stop Signal.

- (b) The movement of trains is controlled by stop signals, which are operated automatically by the passage of train past the signals.

- (c) No Automatic Signal assumes ‘OFF’ unless the line is clear not only upto the stop signal ahead, but also an adequate distance beyond it.

The Automatic Signalling arrangement facilitates to Increase the Line capacity without any additional Stations being constructed and maintained.

Indian Railways: Automatic Block Signalling

So the interlocking system, along with the auto blocking system, must have detected the birthed goods train in the loop line and made it impossible to route Coromandel Express into the loop line.

Data Logger Findings

The latest evidence from the data logger is even more befuddling. The data logger is like the black box of an aeroplane, it logs the events as and when it takes place, and can be reviewed after a crash. The video showing a control panel view replayed in an India Today news report, clearly shows the routes locked and signals green for Coromandel Express to pass. It further shows the Howrah-Yashvantpur SFT passing (trains occupying track are reflected in red lines, to show the circuit is blocked for entry ). It also reflects the two goods trains birthed in their respective loop line.

The second capture from the Data Logger shows Coromandel Express entered the loop at 19:27:40. If this is indeed what happened, then there has been a series of control system failures, bearing in mind the system is tested and rated at SEL 4 by an independent testing agency and not by the manufacturer.

- The point machine responsible to switch lines was in reality set to the loop line, while the control panel had locked the route to the main line, which should just be impossible, as the track circuit would have detected the birthed train as shown in Control Panel Illustration 1, and the interlocking system must have blocked the route change

- The Point detection switch did not detect the status of the route and therefore did not transmit this to the control panel

- The route signal was not pointing towards the loop

- The signal on the main line was green instead of amber

Safe to conclude this would not have been possible in the absence of a serious malfunction or deliberate override if that is even possible in such systems. The former seeming what warrants investigation at first.

A Plausible Crash Scenario

If a train did enter the loop line at Coromandel Express’ speed of 128 kph then the centrifugal effect would have caused the train to derail at the turn into the loop (similar to the Spanish train crash). The physics of this is explained in this New Yorker article. The engine would have sped towards the stationary goods train and the derailed coaches would have hurtled down in a straight line. This is why images of the wreckage above will show the coaches besides the engine as against it being behind the engine as one would expect. One of the tumbling coaches might have have crashed into the rear of the engine, the crow bar effect launched it over the goods train as against it having crashed head-on. The derailed carriages then tail whips into Howrah-Yashvantpur SFT, travelling at a relative speed of 264 kph, crashing two of its trailing carriages. What followed was one of the most tragic event in recent history, 288 dead and 900 injured, in what was to be India’s El Tren de la Muerte (train of death).

Indian Railway Accident Record

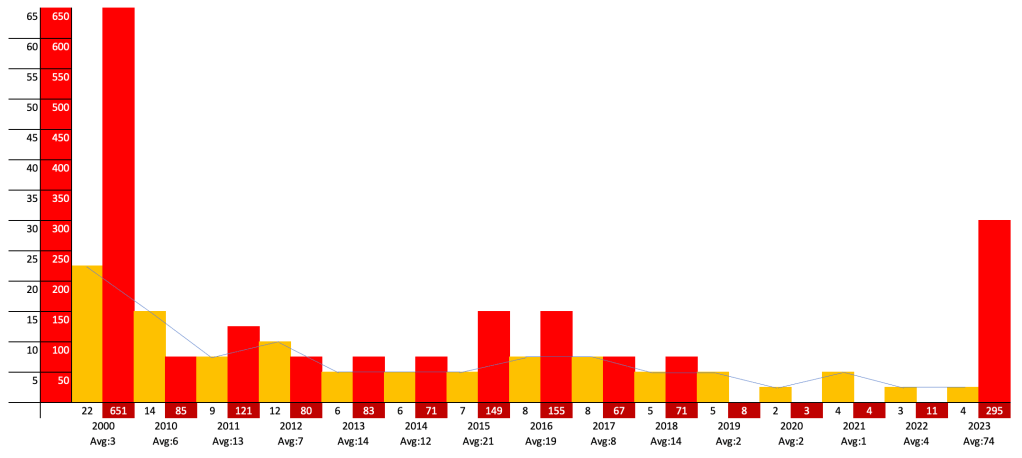

Last 10 years accounted for 913 deaths on account of railway accidents, a 40% increase since 2000-2010. The Orissa disaster alone accounted for 32% of the deaths in the last 10 years, which showed consistent improvement since 2015-16 which was one of its worst. If not for the Orissa disaster the accident fatality number would have improved by 5% over previous years. So is this just a one off, or an act of god?

Recent statistics reveal the risk of death for a train passenger within the EU is around 0.046 fatalities per billion passenger kms per year, US accounts for 0.04 deaths per billion passenger kms, China accounts for 0.02 deaths per billion passenger kms per year, making it one of the safest railway networks in the world, despite its size and population. India’s this year accounted for 0.25 deaths per billion passenger kms and 0.07 average deaths per billion passenger kms over the last 10 years,. This is 17% worse than the 2000-2010 numbers. Even taking the last 10 year average India accounts for 1.5 times higher deaths per billion passenger kms than Europe and United States. India accounts for 3.5 times higher deaths per billion passenger kms when compared to China. Remember the absolutely numbers in U.S are in single digits as against it being in the hundreds dead in India.

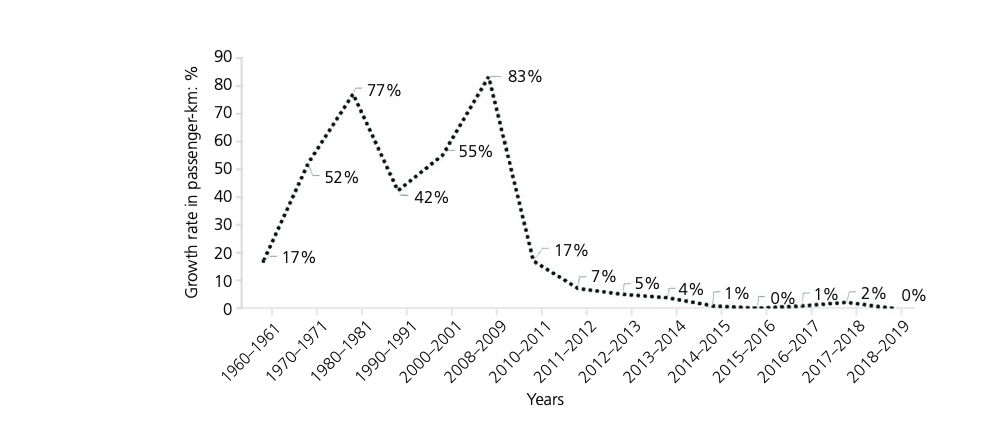

Why is this happening? Has train travel increased significantly in the last few years? Chart 1 shows at near 0% over the last 5 years, not really. There are perfectly sound reasons for why this is the case, like the rising-aspirational middle class preferring safer and faster air travel. However, getting into it would deviate from the core issue of this blog.

Railway Budget and Administration

The Indian Railways was allocated a capital outlay of Rs 2.4 lakh crore in the Union Budget 2023-24. This is the highest ever allocation to the national transporter and continues on the trend followed the previous year with a gross budgetary support of Rs 1.37 lakh crore in fiscal 2022-23.“This allocation is over nine times the amount earmarked in financial year 2013-14,” said Finance Minister Nirmala Sitharaman in a glib remark of one-upmanship, referring to the budget allocation made by the previous Congress government.

The budget outlay included, 75 Vande Bharat trains by August 2023, and a tender to produce 200 additional trains will be awarded soon. Further, in the Budget, the government proposed to manufacture 35 hydrogen fuel-based trains, 4,500 newly designed automobile carrier coaches with side entry, 5,000 LHB coaches and 58,000 wagons. But how many additional staff is the railway going to hire?

Indian railway is the largest employer in the country and has 293,000 open unfulfilled positions, that’s 25% its current strength. The Chart 2 above shows the Staff per Carriage ( total staff divided by the total number of wagons plus coaches) has reduced from 5.83 in 2000 to 3.38 in 2018, and 16% lower than what it was 73 years ago in 1950 . This is as a result of steady rise in number of carriages and reduction in gross staff capacity. To make matters worse Indian Railways has run up a significant operating loss of 15,024.58 crores or a whooping 8% of gross revenue, primarily on account of an increase in staff expenditure over the previous few years, according to a parliamentary committee.

The last 5 years showed a near zero increase in passenger growth, but there is a significant increase in investment in the number of trains in a single year, when there is a hiring shortfall of 25% of total staff capacity, to top it off there is an 8% operating loss due to high staff cost! This is like running a factory that’s running a loss due to high wage costs, despite the high wage costs it remains under staffed and unable to hire, there is low demand for whatever it is producing, yet there is a significant investment into production capacity by doubling capital outlay. While it makes a great show for the Prime Minister to inaugurate several high speed trains, it makes no financial sense.

Investments and Implementation of Railway Security Controls

What is more important, expanding the existing network or number of trains or increasing safety? I think safety is paramount, even if it costs just a single human life, that is a life irreplaceable, no matter how we obfuscate the numbers by normalising it.

Kavach the armour (of god)

One of the major safety measures announced was the much vaunted TCAS system, rechristened Kavach or armour in English. Kavach was even targeted to be exported before it was fully implemented in India by Indian Railways.

The Train Collision Avoidance System (TCAS) or Kavach, which was rolled out for trials last year, is likely to be installed in trains next year, Ministry of Railways spokesperson Amitabh Sharma informed on Saturday.

The remark assumes significance in light of the horrific triple train accident in Odisha’s Balasore on Friday evening, which claimed the lives of close to 300 passengers while leaving 900 injured.

Business Standard: Anti-collision device Kavach to be installed in trains next year: Railways

According to a March 6, 2013 report in the Indian Railway Journal:

HBL Power Systems has been engaged in the development of train protection systems for some time, and pioneered the domestically-developed Train Collision Avoidance System (TCAS) under the guidance of the RDSO.

As the name suggests, TCAS is a comprehensive train protection system which is designed to prevent head-on, rear-end and side-on collisions. In addition, TCAS offers a number of Automatic Train Protection (ATP) features such as Signal Passed at Danger (Spad) prevention, cab signalling and speed control. The system also has a manual SOS function, which can be activated either by the driver or the station supervisor. TCAS can detect and alert incidents of derailment, train splitting and rollbacks, and provides protection against collisions at level crossings.

TCAS comprises three main sub-systems: Loco TCAS, which is the onboard equipment; Station TCAS which is deployed at stations and level crossings; and lastly RFID tags on the tracks. The system uses radios, which operate in UHF frequency for communication between the onboard and stationary equipment. The communication range is designed to maintain safe braking distance in cases where there is a risk of an imminent collision, while each TCAS unit must be able to communicate with all other TCAS units within a 3000m radius.

When the locomotive is within transmission range of the Station TCAS unit, the station equipment acts as the master and provides the movement authority to the locomotives. On longer block sections, when lineside equipment is not within communication range, onboard equipment exchanges data directly between trains to maintain the collision prevention function.

Indian Railway Journal: Domestically-developed TCAS shows potential by Madhu Vatyam

So a “comprehensive train protection system” conceived in 2012 only went into trial in 2022 almost 10 years since its inception? No matter what the current media experts say, that TCAS has nothing to do with the Odisha incident, one cannot rule out it could have reduced the impact, and thereby, potentially the number of casualties. A system that offers number of train protection features other than collision detection and avoidance seems like a system that the Indian Railways is in dire need and must be rolled out expeditiously. While it does not make similar headlines to a to a shiny new super fast express, it would save a few human lives.

In the aftermath of the Odisha tragedy, the railway spokesperson is assuring Indians of what didn’t happen in 10 years will happen in one, by 2024. This can be ruled out, given in 2021 the 2024 target to rollout TCAS was only 4,500 kms according to the Indian Prime Minister. This is out of India’s total rail route length of 102,831 kms, a meagre 4.37% coverage.

HBL Power Systems (HBL) as the lead member of a consortium with Siemens, signed the first contract under Mission Raftar project, with Eastern Railway for deployment of Kavach (TCAS Train Collision Avoidance System) over 260 kms of track and 120 locomotives, from Howrah to Pradhankhanta. The contract price is Rs 286.69 crore including taxes of which HBL’s work share is Rs 205.88 crore; the contract is scheduled to be completed in 700 days.

HBL received a purchase order from ICF for the supply of 46 sets of Kavach, to be installed at the time of manufacture of the trainsets, at a total price of Rs 31.66 crore including taxes. Deliveries begin in Nov 2022 and is scheduled to be completed by Jul 2023.

The tender in West Central Railway is for deployment of Kavach over 549 kms of track and 87 locomotives, for a bid price of Rs 353.84 crore including taxes. The tender in Western Railway is for deployment of Kavach over 96 kms of track, for a bid price of Rs 81.67 crore including taxes. The contracts for these tenders are expected to be awarded shortly.

02 Sep 2022 Business Standard: HBL Power Systems wins multiple contracts for supply of Kavach

According to the above report contracts was awarded in Sep 2022 for a paltry 260 kms. Another 645 kms were in the works yet to be awarded. According to another report Kavach is installed on 1,098 kms and 65 trains. That accounts for just 2,003 kms or 45% of the 2024 target. This could mean even the sub par 2024 targets won’t be met?

The system was installed on 65 locomotives, contracted to be installed on 166 locomotives and tenders to be awarded for another 87 locomotives, out of total fleet of 13,215 locomotives. This accounts for a coverage of just 2.4% of the fleet. This would mean 98% of track lines and locomotive fleet will rely on the current system. Surely investing in high speed trains must be slowed until we have created adequate TCAS coverage on high speed routes?

As of March 2020, only around 3,309 km (2,056 mi) of the route uses automatic block signalling for train operations – concentrated in high density routes, large cities and junctions. Remaining routes are based on absolute block signalling.

2022 CAG Report Findings

Derailment in India (Union Government Performance Audit Report no 22. of 2022)

Poor Track Maintenance

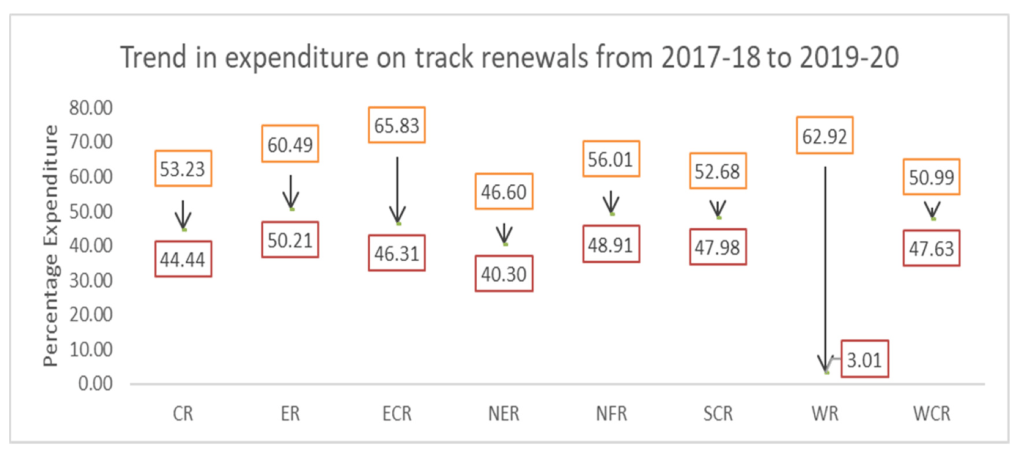

The report identified 167 out of 217 or 75% of train accidents were on account of derailment. 33% of derailment was on account of the Engineering Department and 82% of those derailments were on account of poor track maintenance.

- It was identified, there was a 30-100% shortfall in Monitoring by Track Recording Cars carried out to assess the structural and geometrical health of the tracks.

- The status of outsourcing Track Maintenance Activities was found to be insufficient against the required number of work force of the Civil Engineering department. The percentage of vacancies in IR for Civil Engineering department ranged between 9-36 per cent.

- Over the years, extent of mechanized maintenance gained importance for reliable track maintenance with high degree of precision and quality with minimum dependence on human factor. Audit noted that 517 track maintenance machines were deployed during the period from 2017-18 to 2020-21 , out of the total available machine days 7,54,820, the machines remained idle for 1,20,135 (16 per cent) machine days.

- Audit found track welding fell short by 23-40%, where no welding was done between 2017 to 2021 despite 86.01% of contracts being awarded. Ultrasonic flaw detection testing shortfall was over 50% of welds. So the fact welding was never performed and flaw detection was not performed could result in them not detecting un-welded track lines.

- In order to bring efficiency and effectiveness in track management and maintenance practices, Railways has also introduced e-enabled track maintenance practices on Web-Enabled IT platform known as Track Management System (TMS).

- 794 officials dealing with track maintenance activities were not given training

- Field staff were not provided walkie talkies, safety helmets, or had poor quality gloves and torch lights

CAG Report Findings

The deficiencies in setting up a foolproof system of learning from past mistakes are a serious impediment to fulfillment of one of the main objectives of the accident inquiry reports of preventing recurrences of incidents of derailments.

The Railway administration had failed in achieving the important objective of monitoring the preventive action in respect of the recommendations made by the Inquiry Committees.

There was increasing trend on IR towards expenditure on non-priority works against the guiding principles of Rashtriya Rail Sanraksha Kosh (RRSK) deployment framework. The sole purpose of creating a separate dedicated fund for financing safety related works was defeated, as safety related works were held up due to fund constraints.

It was found that there were severe shortfall in track inspection across the board. And the audit committee reported “Thus, failure in conducting the periodical inspections of the permanent way as provided in the IRPWM-2020, would lead to poor condition of track and resultant accident. Possibility of derailment due to poor condition of track cannot be ruled out.”

Conclusion

There has been a gross under allocation of funds towards railway safety controls, a meagre 8% of the much flaunted Rs. 240,000 crores budget was allocated towards track maintenance and implementation of the anti collision systems. There has been misallocation of RRSK funds towards priority safety expenditures. The anti-collision system implementation has significantly lagged behind schedule and the coverage abysmally low, leaving 98% of the lines exposed to collision incidents. There are significant gaps in safety controls and track maintenance, resulting in derailment, in a recently concluding audit finding. Finally, the railway is grossly understaffed.

Instead of addressing hiring and safety issues the focus has been on populist programs to expand the number of high speed trains like Vande Bharat. In the absence of adequate safety controls, increasing the number of high speed trains could significantly increase the accident rates. High speed trains could, in the absence of safety controls, increases the risk of fatality of these accidents manifolds, putting many more lives at risk.

It was announced on the 7th June 2022, within two days of the crash, Central Bureau of Investigation (CBI) were officially taking over the investigation into Odisha’s Balasore train crash, raising FIR under Sections 337 (whoever causes hurt to any person by doing any act so rashly or negligently as to endanger human life), 338 (causing grievous hurt by an act endangering life or personal safety of others), 304 A (causing death by negligence), and 34 (acts done by several persons in furtherance of common intention) of the Indian Penal Code (IPC).

This presumes human intervention as the only plausible cause, even before the Commission for Railway Safety, an independent body setup specifically to investigate railway accidents, had barely started their investigation. Why not let both investigations proceed in parallel, human intervention and system failures?

This at the outset smells of a cover up, which could result in systemic railway safety issues remaining unidentified or unaddressed. Ten years onwards, it may very well be 913 dead and counting and one can’t be certain, if we have seen the last of “El Tren de la Muerte”.